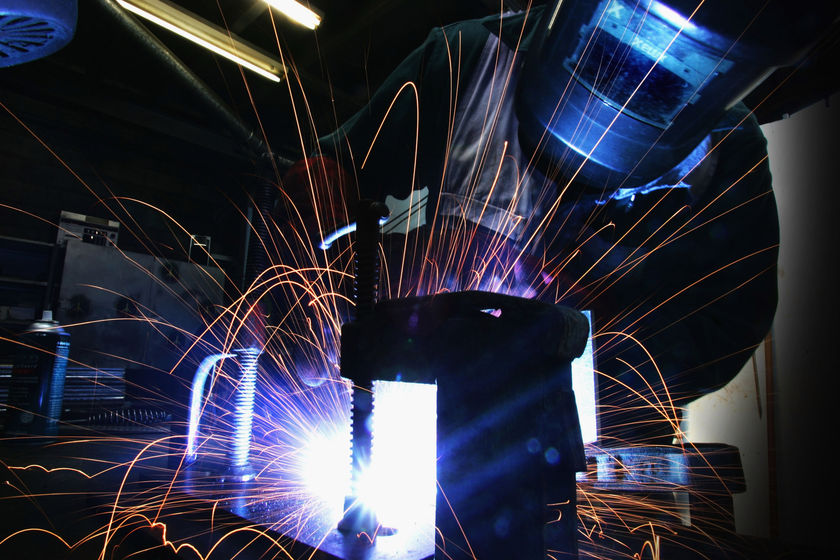

Manufacturing

Helping Canada’s manufacturing sector lower their energy and commodity costs for 28 years

Helping Canada’s manufacturing sector lower their energy and commodity costs for 28 years

Managing the daily operations of a manufacturing facility is complex to say the least. Acquiring and applying the skills and knowledge specific to certain types of production methodologies, and the procurement of materials unique to the product being manufactured, leaves little time for anything else.

Understanding the energy markets, purchase options and differences in utility rates and regulations is, however, a grey area for those who do not dedicate their full attention to this discipline. After performing a review for a large aircraft manufacturer, we found that the utility rate being applied to their natural gas account was no longer appropriate. By structuring the right action plan, we arranged for implementation of an alternative rate structure and within a 12 month period the company reduced its natural gas costs by over $200,000.

In another instance, we found a large recycling facility was paying nearly 15% more for their bulk oxygen than they should be. After providing a strategy, they were able to alter their supply agreement and begin saving within just a few weeks of receiving our report. The net result after just one year was a realized cost savings of $132,000.

“This is the kind of expertise that En-Pro brings to the table. We provide the unknown information that allows each client to level the playing field with their supplier and acheive the lowest possible rate for each commoditiy. We do this without disrputing the existing supplier relationship as most often a change in supplier is not required. Often times the supplier is not even aware of the lower price options available in their marketing area.” – Paul Kilistoff – Energy Cost Advisor